Grinding machines are essential tools in manufacturing and metalworking industries. They play a significant role in shaping, finishing, and improving the surface quality of various materials, particularly metals. These machines use abrasive wheels to cut away tiny chips of material, providing smooth finishes and precise dimensions. As industries expand and demand for high precision grows, grinding machines have become more diverse, catering to specific tasks and applications. Understanding the different types of grinding machine and their uses is vital for anyone involved in machining, fabrication, or production.

What is a Grinding Machine?

A grinding machine is a power-driven tool that employs abrasive wheels to remove material from a workpiece. Unlike cutting tools, grinding relies on tiny abrasive grains bonded on a wheel’s surface to perform cutting at high speed. The primary purpose of grinding is to achieve superior surface finishes, tight tolerances, and accuracy that conventional machining processes may not deliver. Grinding machines are widely used in automotive, aerospace, construction, tool manufacturing, and many other industries.

Importance of Grinding Machines

Grinding machines offer several advantages that make them indispensable in modern industries. They provide precision, allowing manufacturers to achieve accuracy down to microns. These machines also improve surface quality by producing smooth finishes, which is crucial in applications like engine components and medical devices. Additionally, grinding enhances the lifespan of tools and parts by removing irregularities and stress points, ensuring efficiency and reliability.

Types of Grinding Machines

There are numerous types of grinding machines, each designed for specific applications. The following sections explore the most common types and their uses in detail.

Surface Grinding Machine

Surface grinding machines are among the most widely used. They are primarily employed for producing flat surfaces with excellent accuracy. The workpiece is placed on a table, which moves back and forth under the rotating grinding wheel. This machine can work on both metallic and non-metallic materials.

Uses of Surface Grinding Machine:

- Creating flat and smooth surfaces on workpieces

- Sharpening tools and dies

- Preparing surfaces for coatings or further machining

- Finishing hardened steel parts

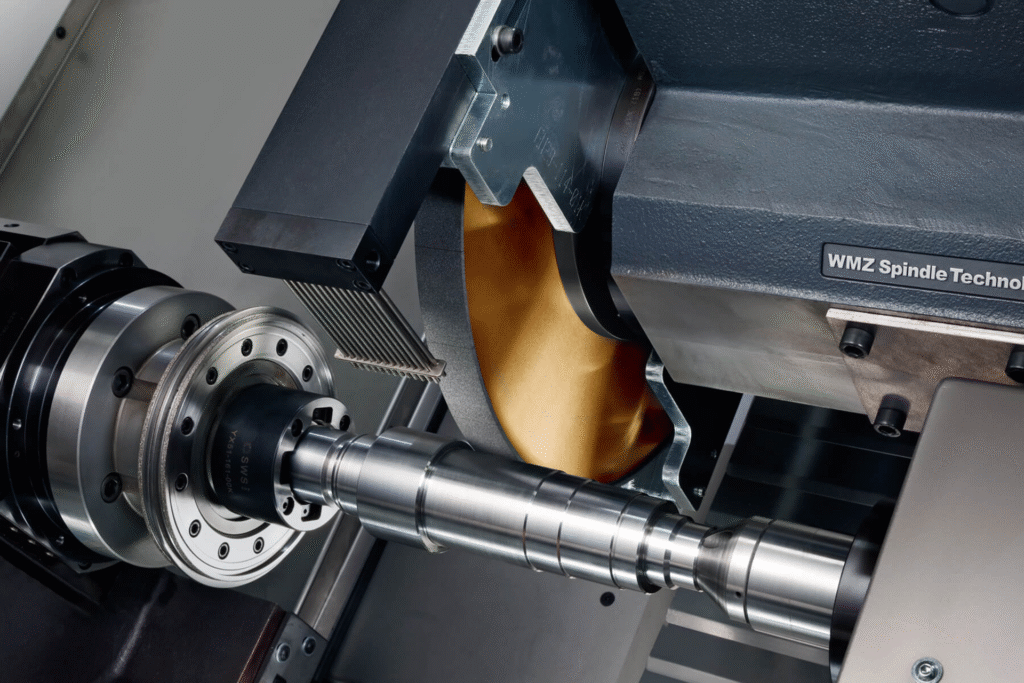

Cylindrical Grinding Machine

Cylindrical grinding machines are designed for grinding the external surface of cylindrical workpieces. The workpiece rotates as the grinding wheel moves along its surface to achieve the desired finish and dimension. These machines can handle both small precision parts and large industrial components.

Uses of Cylindrical Grinding Machine:

- Grinding shafts, rods, and axles

- Finishing hydraulic cylinders

- Producing smooth finishes on engine parts

- Precision grinding of industrial rollers

Centerless Grinding Machine

Centerless grinding machines are unique because they do not use centers to hold the workpiece. Instead, the workpiece is supported by a blade and positioned between a grinding wheel and a regulating wheel. This design allows for continuous, high-volume production with exceptional accuracy.

Uses of Centerless Grinding Machine:

- Mass production of cylindrical parts

- Manufacturing automotive components such as fuel injectors

- Grinding bearing races and bushings

- Producing precision medical instruments

Internal Grinding Machine

Internal grinding machines are specialized for finishing the internal surfaces of cylindrical or conical holes. A small grinding wheel fits inside the workpiece and removes material to achieve accurate dimensions.

Uses of Internal Grinding Machine:

- Grinding the inside diameter of bearings

- Finishing internal bores of gears and cylinders

- Producing high-precision bushings

- Enhancing the accuracy of engine components

Tool and Cutter Grinding Machine

Tool and cutter grinding machines are highly versatile and used to sharpen or shape various cutting tools. They can handle tools like drills, milling cutters, and reamers, restoring them to sharp and efficient working conditions.

Uses of Tool and Cutter Grinding Machine:

- Sharpening worn-out cutting tools

- Grinding custom cutting tool profiles

- Reconditioning drills and milling cutters

- Extending the lifespan of expensive tooling

Gear Grinding Machine

Gear grinding machines are dedicated to producing high-precision gears. They remove material from gear teeth using specialized grinding wheels, ensuring correct shape and perfect meshing with other gears.

Uses of Gear Grinding Machine:

- Manufacturing gears for automotive transmissions

- Producing aerospace gear systems

- Finishing high-precision industrial gears

- Ensuring accuracy in robotics and machinery components

Bench Grinding Machine

Bench grinders are compact grinding machines mounted on a bench or table. They are mainly used for hand grinding tasks, such as sharpening small tools and removing rust or burrs.

Uses of Bench Grinding Machine:

- Sharpening chisels and knives

- Removing burrs and imperfections

- Polishing small metal surfaces

- General workshop maintenance tasks

Belt Grinding Machine

Belt grinding machines use abrasive belts instead of grinding wheels. These machines are highly effective for finishing and polishing flat or contoured surfaces. They are widely used in fabrication and finishing industries.

Uses of Belt Grinding Machine:

- Surface finishing of metals and plastics

- Removing weld marks and imperfections

- Polishing stainless steel and aluminum parts

- Shaping and smoothing woodworking projects

Jig Grinding Machine

Jig grinding machines are highly precise and are used for finishing complex shapes and holes that demand extreme accuracy. They are commonly employed in tool and die making.

Uses of Jig Grinding Machine:

- Grinding complex and intricate cavities

- Achieving high accuracy in mold manufacturing

- Producing aerospace and defense components

- Precision finishing of dies and fixtures

Pedestal Grinding Machine

Pedestal grinders are similar to bench grinders but are mounted on a pedestal stand, making them suitable for heavier and larger workpieces. They are commonly found in workshops and fabrication units.

Uses of Pedestal Grinding Machine:

- Sharpening large cutting tools

- Deburring heavy metal parts

- Grinding welds and rough edges

- Preparing surfaces for painting or coating

Factors to Consider When Choosing a Grinding Machine

Selecting the right grinding machine depends on several factors, including the material, required accuracy, production volume, and cost considerations. Some machines are designed for mass production, while others focus on achieving extreme precision. Users must also evaluate the maintenance requirements, energy consumption, and operator skill levels before making a decision.

Conclusion

Grinding machines are vital tools in modern manufacturing, offering precision, efficiency, and versatility. From surface grinders that create flawless flat surfaces to gear grinders that produce perfectly meshed gears, each type of grinding machine serves a unique purpose. Understanding the different types of grinding machines and their uses helps industries optimize production, reduce costs, and achieve superior product quality. As technology advances, grinding machines will continue to evolve, providing even higher accuracy and efficiency in industrial applications.