Proper maintenance of cooling systems is essential to ensure peak performance, energy efficiency, and a longer lifespan. Whether you are managing a residential air conditioning unit or a large industrial cooling system, neglecting routine care can lead to increased energy bills, frequent breakdowns, and reduced effectiveness. By following structured maintenance practices, you can keep your cooling systems running efficiently throughout the year.

Understanding Your Cooling System

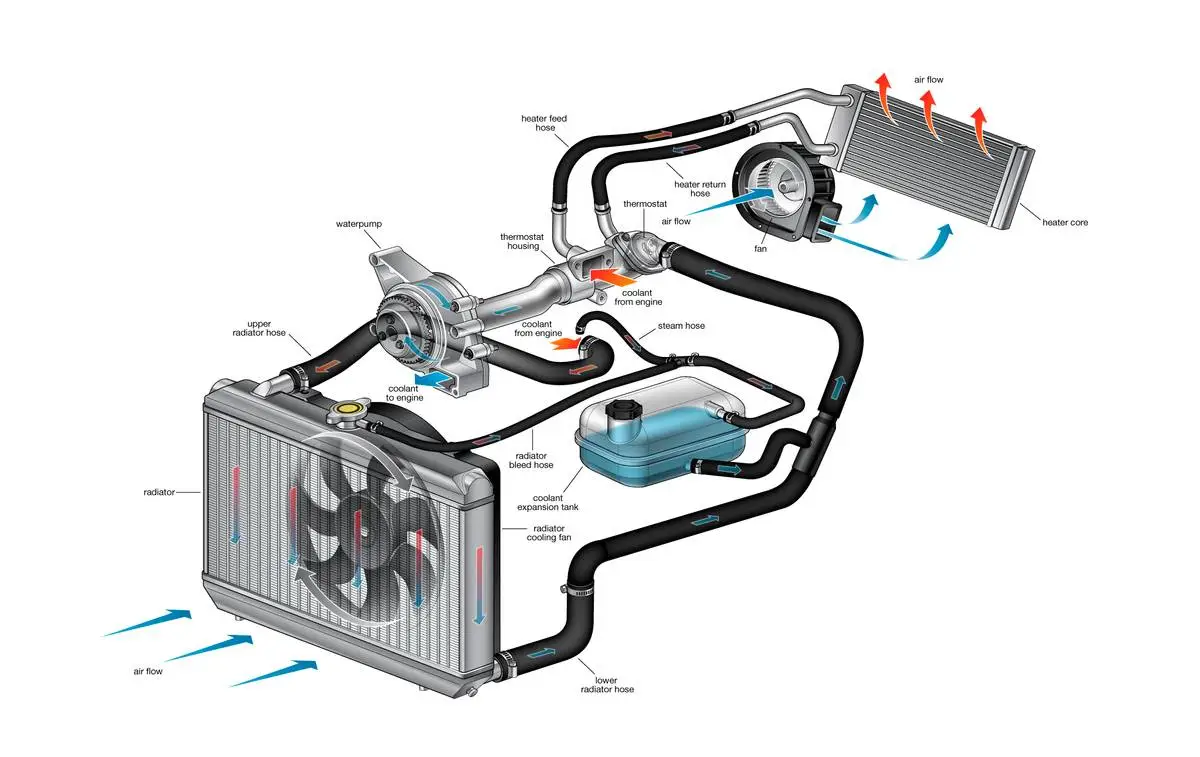

Cooling systems operate by transferring heat from one area to another, often using refrigerants, fans, and heat exchangers. Common types include central air conditioners, split systems, chillers, and HVAC units. Each system relies on several components working harmoniously, such as compressors, condensers, evaporators, and filters. Understanding the function of each component allows you to identify potential issues before they escalate into major problems.

Efficiency is not only about keeping the system running but also about ensuring it runs under optimal conditions. When a system is clogged, leaking, or overworked, it consumes more energy, leading to higher utility bills. Regular maintenance ensures that the system operates smoothly and provides consistent cooling performance.

Regular Inspection and Cleaning

One of the simplest ways to maintain cooling systems is through regular inspections. This includes checking the system for any visible signs of wear or damage. Look for leaks, rust, or unusual noises, which can indicate underlying problems.

Cleaning is equally important. Dust, dirt, and debris can accumulate on coils, filters, and vents, reducing airflow and heat transfer efficiency. Cleaning the evaporator and condenser coils helps maintain the system’s cooling capacity. For residential systems, filters should be cleaned or replaced every one to three months. Industrial systems may require more frequent cleaning due to higher usage.

Monitoring Refrigerant Levels

Refrigerant is the lifeblood of most cooling systems. Low refrigerant levels can force the system to work harder, causing excessive wear on the compressor and reducing cooling efficiency. Monitoring refrigerant levels and topping up when necessary is critical.

It’s important to hire certified technicians for this task because handling refrigerants improperly can harm the environment and violate regulations. Regular checks ensure that your cooling systems maintain the correct pressure and temperature, improving energy efficiency and performance.

Maintaining Airflow

Proper airflow is essential for efficient cooling. Blocked or restricted airflow can cause uneven cooling, ice formation on coils, and increased energy consumption. Inspect ducts, vents, and fans for obstructions, and ensure that air filters are clean.

In larger cooling systems, ductwork should be checked for leaks or damage. Sealing leaks and ensuring smooth airflow can significantly improve the efficiency of the system. Even minor improvements in airflow can reduce the load on compressors and extend the life of your cooling systems.

Lubricating Moving Parts

Cooling systems contain several moving parts such as fans, motors, and compressors. Over time, these components can wear out due to friction, heat, and dust. Lubricating moving parts according to manufacturer recommendations helps reduce wear and prevents unexpected failures.

Proper lubrication also ensures quieter operation and smoother performance. While some components may be sealed and maintenance-free, motors and fan bearings often require periodic attention. Always use lubricants recommended by the manufacturer to avoid damaging the system.

Checking Electrical Connections

Faulty electrical connections are a common cause of cooling system malfunctions. Loose wires, corroded terminals, or worn-out components can reduce efficiency and pose safety risks.

Regularly inspecting electrical components such as relays, capacitors, and circuit breakers can prevent sudden breakdowns. Tightening connections, replacing worn parts, and ensuring proper voltage supply contributes to stable operation and energy efficiency.

Optimizing System Settings

Many modern cooling systems come with programmable thermostats and automated controls. Setting the system to operate according to actual cooling needs can prevent unnecessary energy consumption.

For residential systems, adjusting the thermostat by a few degrees when away from home or during cooler periods can reduce energy usage. In industrial settings, proper scheduling and load management ensure that cooling systems operate only when necessary, optimizing performance and minimizing wear.

Seasonal Maintenance

Cooling systems often require seasonal maintenance to prepare for high-demand periods. Before summer, inspect the system thoroughly to ensure it can handle increased cooling loads. This includes cleaning coils, checking refrigerant levels, inspecting fans and motors, and testing electrical components.

Winter months are also important for maintenance. While the system may not be in heavy use, components can still suffer from dust accumulation, moisture, and corrosion. Seasonal checks help prevent issues from developing when the system is restarted.

Professional Servicing

While routine maintenance can be handled by homeowners or in-house staff, professional servicing is essential for comprehensive care. Certified technicians have the expertise, tools, and knowledge to diagnose hidden problems, perform precise repairs, and maintain system efficiency.

Professional servicing may include leak detection, advanced cleaning methods, refrigerant recharging, performance testing, and component replacements. Regular professional checks ensure that your cooling systems operate at peak efficiency, preventing costly downtime and extending the system’s life.

Energy Efficiency Upgrades

Maintaining cooling systems is not only about repairs and cleaning. Upgrading system components can significantly enhance efficiency. Modern thermostats, high-efficiency compressors, variable-speed fans, and energy-efficient motors can reduce energy consumption and improve performance.

For older systems, retrofitting with modern components or replacing outdated equipment may be more cost-effective than frequent repairs. Investing in energy-efficient upgrades reduces long-term costs while supporting environmental sustainability.

Monitoring Performance Metrics

To maintain maximum efficiency, track your cooling system’s performance metrics. Key indicators include energy consumption, cooling output, airflow rates, and compressor cycles.

Monitoring these metrics helps identify declining performance early. Smart thermostats, energy meters, and system management software provide real-time insights, enabling proactive maintenance. Consistently monitoring performance ensures that your cooling systems operate optimally and prevents costly surprises.

Conclusion

Maintaining your cooling systems for maximum efficiency requires a combination of regular inspections, cleaning, professional servicing, and performance monitoring. Paying attention to airflow, refrigerant levels, electrical connections, and moving parts ensures that the system operates smoothly and consumes minimal energy.

By adopting a structured maintenance routine and investing in periodic upgrades, you can extend the lifespan of your cooling systems, reduce energy bills, and enjoy reliable performance year-round. Efficiently maintained systems are not only cost-effective but also contribute to a more sustainable and environmentally responsible operation.

Proper care of your cooling systems transforms them from simple appliances into long-term investments that provide comfort, reliability, and energy savings.